Stirrer-Blender

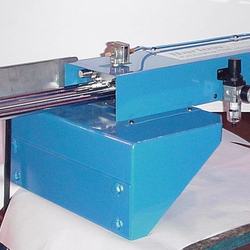

Utilized in the initial stage of glass processing, a Stirrer-Blender mixes or blends colour in molten glass before entering the forming stage.

A Stirrer handles the blending of colorant, while Blender ensures proper consistency.

Forehearth Colorant Stirring Mechanisms are found around the world as one of the leading pieces of Glass industry equipment.

· Economical and versatile

· Work between the furnace and forming machine

· Designed to suit forehearth size and glass pull requirements

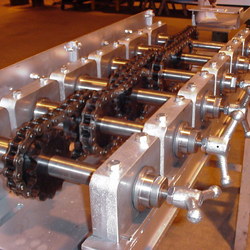

· Barlow ‘Colorant Stirring Mechanism’ supplied with 1 to 6 banks

of 1 to 6 stirrers

· Mechanism supported by rigged frames with pullout heads for

easier maintenance

· Internal air cooled bearing housings with protective heat shields

· Alloy steel shafts and 3 piece cast stainless steel chucks

· Control panel, motors, and inverters sized to suit

number of spindles

· Designed and built to function in extreme operating environments